Tube Streching

The PLASTECH TUBE STRETCHING SYSTEM is a new fully patented and protected tube manufacturing process. The process enables the production of tubes by a simple and cost effective method.

The tubes produced are of excellent quality. With suitable materials transparency is improved, and the process offers significant improvement in the capability of obtaining enhanced decoration options.

The tube stretching process:

|

|

| The process is based on injection moulded preforms which are mechanically stretched |  |

| and thus extended 2-4 times in the axial direction until the desired dimensions are obtained |  |

| After stretching the tubes are trimmed |  |

| and transferred continuously to the capping and |

|

| decoration processes. |  |

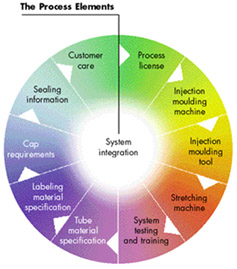

These process steps are all integrated in the tube stretching equipment. For starting up the new tube manufacturing system you need:

- An injection moulding mahcine

- A stretching machine

- A set of tooling

- A license

- Know-how

PLASTECH supplies you an integrated package including all.

Have a video look into the streching process - link